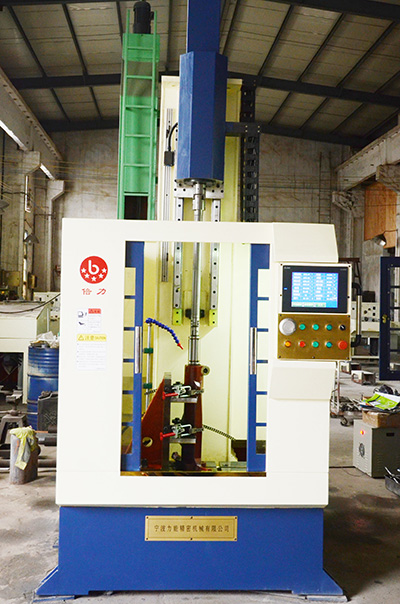

2M2208S-500 vertical CNC honing machine

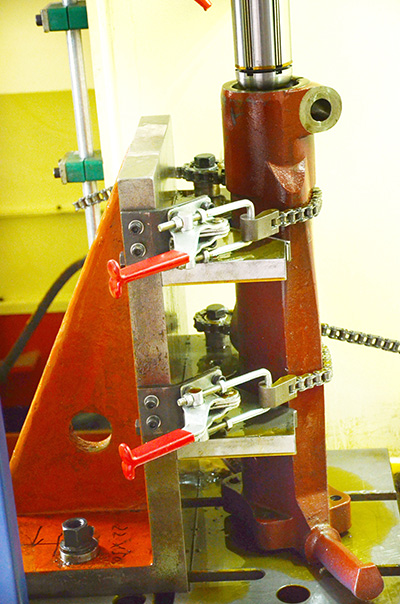

First, the basic parameters of the processing part aperture:

1. Aperture: The range of equipment can be processed: Φ20-Φ200mm

2, hole length: equipment can be processed hole length range: 500mm, 1000 mm, 1500 mm

3 Processing accuracy:

Roundness: ≤0.002mm

Cylindricity: ≤0.003mm

Surface roughness: Ra0.1-0.2

Second, the basic parameters of the machine:

Spindle speed: 30-960 rev / min (frequency stepless speed regulation)

Spindle motor: 2.2KW 10-50Hz variable frequency motor (6 pole)

Stroke servo motor: 5KW

Stroke length: 20-650mm

Stroke speed: 0-35m/min

Feed servo motor: 0.75KW

Feed accuracy: 0.001mm (minimum feed, adjustable)

Stop brake for spindle and stroke: electronic brake (matchable adjustment)

Oil pump motor: 125W

Work surface size: 500*700mm

Dimensions: 1580 × 1800 × 3200 (length * width * height)

Net weight of machine tool: about 3200Kg

Power: 380V 50Hz three-phase four-wire

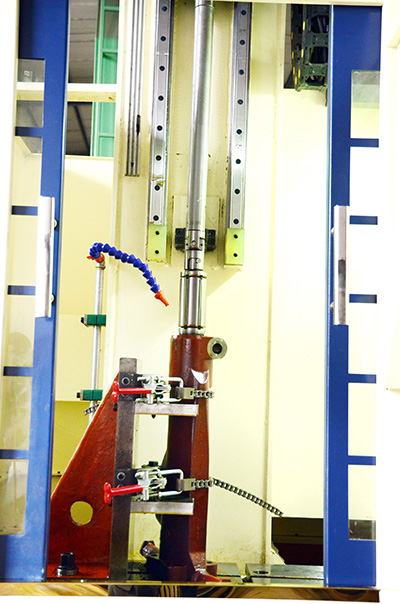

Third, the machine features:

1. Large processing range (Φ20-Φ200mm)

2. The roundness of the workpiece can be up to 2-3um, the straightness can be less than 5um, and the finish is Ra0.2-0.4um.

3, the spindle and stroke speed control are infinitely variable speed, easy to match and adjust the honing netting, the stroke has a short stroke local honing function.

4, France Schneider Electric and Japan Mitsubishi PLC, with "manual" "automatic" "time" and other size control functions

5. The spindle bearing adopts Swedish SKF bearing, the sliding guide and the transmission spindle adopt Japanese THK.

6, the parts are automatically stopped after processing to size, the tolerance of parts can be controlled at 0.01mm.

7, the price of domestic machine, the performance of imported machine, vertical deep hole honing

|  |  |